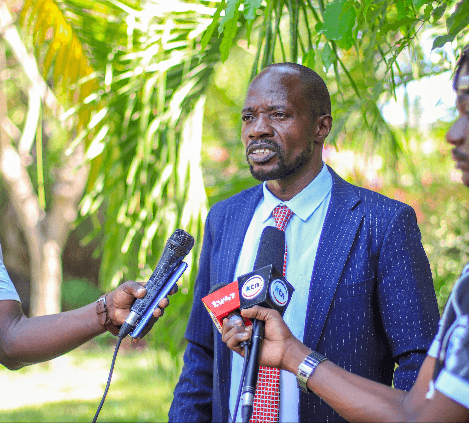

Production manager Maurice Munyao /SHARON NGARI

Production manager Maurice Munyao /SHARON NGARI

Unique management of production and printing operations has seen the Star press dramatically reduce waste from 24 per cent to under five percent—a major efficiency milestone that comes as the newspaper marks 18 years since its launch in 2007.

“The right match of skill set, use of the latest technology and waste-cutting measures have seen the quality of the print improve over time and the paper become more readable,” said Maurice Munyao, the Star’s factory production manager.

He explained that the teamwork within the production unit has played a vital role in ensuring efficient and timely printing.

This, in turn, has enabled the smooth dispatch of copies for distribution, ensuring readers can always find their favourite paper on news stands across the country on time.

“I joined the team in 2016 and through my time, I have endeavoured to minimise waste, cut down on returns and ensure improved quality within the tight fiscal environment,” he said.

At the time of his arrival, the Star had already carved out a unique identity as a bold and credible source of political, human interest and sports news. However, “…[the] quality of the print was its undoing”, affecting brand perception and customer satisfaction.

His boss at the time, Agnes Kalekye, who was the Star’s chief operations officer, gave him the room to innovate met.

“She was supportive, but initially not sure if I would meet the target of cutting down on printing waste from 24 per cent to five per cent,” he said.

“I assured her that I would meet the target because waste levels were unacceptable. Together with my team, we were able to exceed the target by one per cent. We cut it down to four per cent in four months.”

Beyond reducing waste, another key indicator of progress has been the sharp drop in return rates—the number of unsold newspapers that are sent back.

When he took over the printing operation, the return rate stood at a staggering 47 per cent. But as print quality and legibility improved, that figure dropped significantly.

“Readers don’t just love the content of the paper, but also the packaging of the content,” Munyao said. “That is why I took it upon myself to ensure the quality of the packaging was high.”

The turnaround has not only saved costs but also helped elevate the brand's reputation and reliability in a competitive media landscape, especially at a time when print publications are under pressure from digital platforms.

INSTANT

ANALYSIS:

The Star press’s

reduction of waste to below five per cent highlights how operational efficiency

and print quality can drive sustainability and reader satisfaction. It's a

timely win as the paper celebrates 18 years of impactful journalism.